What is Leak Detection And Repair (LDAR)?

Leak Detection and Repair (LDAR) programs are critical components of environmental compliance strategies across various industries. These programs are designed to identify, assess, and mitigate leaks of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) from process equipment. The primary objectives of LDAR include preventing uncontrolled releases of harmful gases, ensuring workplace safety, and minimizing environmental impact. LDAR involves a systematic approach, incorporating advanced technologies for leak detection, rigorous maintenance protocols, and comprehensive reporting to regulatory bodies.

Why It’s Important

The significance of LDAR cannot be overstated. Firstly, it plays a pivotal role in protecting worker health and safety by reducing exposure to toxic substances. Secondly, LDAR is essential for environmental conservation, limiting the release of pollutants that contribute to air quality degradation and climate change. Moreover, effective LDAR programs help industries avoid significant fines and penalties associated with non-compliance to environmental regulations. Additionally, by identifying and rectifying leaks, companies can achieve substantial cost savings through the reduction of product losses.

Industries Typically Affected

Industries that commonly implement LDAR programs include oil and gas, chemical manufacturing, pharmaceuticals, heat pump technologies, and petrochemicals. These sectors are characterized by extensive use of pipes, valves, pumps, and tanks, making them susceptible to leaks of gases and liquids. Compliance with LDAR regulations is not just a legal obligation for these industries but also a critical element of operational integrity and sustainability.

Main Components of an LDAR Program

An effective LDAR program is comprehensive, encompassing several critical components that work in concert to ensure environmental compliance and operational safety. These components include:

- Identification of Components

The first step involves cataloging all components in a facility that could potentially leak VOCs or HAPs. This includes valves, pumps, connectors, and any other equipment susceptible to leaks. Accurate identification and tagging are crucial for the systematic monitoring and maintenance of these components. - Leak Detection Technologies

Implementing the right leak detection technologies is at the heart of any LDAR program. Technologies range from traditional methods like soap-bubble tests to advanced techniques involving infrared cameras and acoustic detectors. ZOOK’s innovative products, such as the RDI, BA, and BI Series Burst Sensors, represent reliable and accurate leak detection technology. - Monitoring and Measuring

Regular monitoring and measuring of emissions from identified components are essential. This process involves scheduled inspections using the chosen detection technologies to quantify leak rates and identify any equipment exceeding permissible emission levels. - Repair and Maintenance

Once leaks are detected, prompt repair and maintenance of the leaking components are necessary to mitigate emissions. The effectiveness of an LDAR program is significantly determined by the speed and efficiency with which repairs are carried out. - Record-Keeping and Reporting

Maintaining detailed records of all LDAR-related activities, including inspection dates, detected leaks, repair actions, and emission levels, is a regulatory requirement. These records are critical for demonstrating compliance with environmental standards and for internal assessments of program effectiveness. - Training

Training personnel involved in the LDAR program is vital to ensure they are proficient in using detection equipment, understanding regulatory requirements, and implementing best practices for leak detection and repair.

LDAR and Rupture Disks

Rupture disks, also known as bursting discs, serve as a fail-safe mechanism designed to protect processing equipment and personnel from the dangers of overpressure conditions. These precision-engineered devices are integral to many pressure relief systems, providing an immediate response to excessive pressure by rupturing, which effectively relieves pressure and prevents potential equipment failure or catastrophic incidents. They are often paired with pressure relief valves (PRV) – whether in series or parallel – as the rupture disk conveys many benefits including leak prevention.

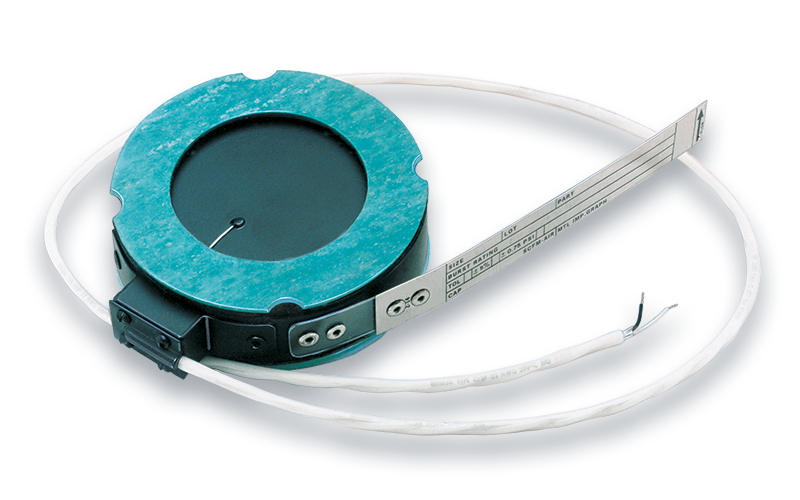

Rupture disks can be accompanied by an array of burst detection capabilities. ZOOK’s offerings, such as the RDI, BA, and BI Series rupture disk burst sensors and indicators, integrate seamlessly into the fabric of an LDAR program, addressing several of its core components. Our products enhance the detection and monitoring capabilities of LDAR programs, ensuring leaks are swiftly identified.

Solutions: ZOOK's Comprehensive Burst Indication Offering

ZOOK stands at the forefront of providing innovative solutions tailored to the demanding requirements of LDAR programs. Our products, such as the RDI, BA, BI Series Burst Sensors, and the ZAM Plus Rupture Disk Alarm Monitors, embody the pinnacle of reliability and precision in leak detection technology. Some of the following solutions can be used with or without rupture disks.

ZOOK’s Products Capabilities:

RDI Series Rupture Disk Indicator: A cost-effective, standalone burst indication device for leak detection, rupture disk, or safety relief valve applications. Offers immediate burst notification as a standalone solution or in tandem with metal or graphite rupture disks. It’s designed for easy installation and requires no routine maintenance.

LD Series Leak Detector for RDI Series: Integrated with the RDI Series as a simple device to detect leakage. When a build-up or pressure occurs, the LD seal will bulge and activate the RDI sensor and send a signal of leakage detection.

RDI-S Series Rupture Disk Indicator: The RDI-S is for Sanitary Installations and Applications (-S). This device is identical to the RDI but is used in Sanitary Tri-Clamp Fittings.

BA Series Rupture Disk Burst Sensor: Features re-settable burst detection with optional leak detection capabilities. The BA Series is adaptable to virtually all makes and types of rupture disks, including graphite types, ensuring broad applicability and minimal downtime.

LD Series Leak Detector for BA Series: Integrated with the BA Series as a simple device to detect leakage. When a build-up or pressure occurs, the LD seal will bulge and activate the BA sensor and send a signal of leakage detection.

BI Series Integral Burst Indicator: Integrates directly into the vent side of rupture disk assemblies, providing immediate notification upon disk rupture. Its design is resistant to back pressure effects and is compatible with ZOOK’s flat-seat metal and sanitary rupture disks.

ZENSOR Rupture Disk Burst Sensor: Specifically designed for use with ZOOK’s Impervious Graphite Rupture disks, the ZENSOR adds an extra layer of safety and reliability with its TFE-coated rupture disk and tantalum sensing element for maximum corrosion resistance.

Note: Each of our Burst Indication and Sensor options comes with multiple plug end connections. The most common being a Red and White wired weatherproof 2 pole plug connector for simple, quick and easy installation.

ZAM Plus Alarm Monitors: These monitors are designed to work seamlessly with ZOOK’s burst indication devices, providing immediate local or remote warning of a ruptured disk. The ZAM series is intrinsically safe and capable of integrating into complex systems to ensure continuous monitoring and compliance. The ZAM Series is offered in a 2, 4, 6 or 8 Channel design.

ZOOK’s comprehensive offering not only meets the stringent requirements of modern LDAR programs but also sets new standards for safety, reliability, and operational efficiency. ZOOK has most of these designs in inventory and ready for immediate delivery. Our solutions are engineered to provide immediate, accurate detection of system breaches, allowing for swift corrective actions. By choosing ZOOK, industries benefit from enhanced compliance, protection, and peace of mind, ensuring the safe and sustainable operation of their facilities.