Pulp and paper play a crucial role in supporting industries such as communication, packaging, printing, and publishing by processing and providing essential materials.

Solutions for

Pulp & Paper

OVERVIEW

From the processing of wood into wood pulp, which consists mainly of cellulose fibers the main component of paper, to various batch finishing and recovery processes, heated pressurized vessels require over-pressure protection provided by ZOOK rupture disks.

COMMON APPLICATIONS

Bulk Storage

Silos containing wood chips and pulp raw material generate combustible dust. Rupture disks and vent panels provide instantaneous relief of excess pressure within the storage tank.

Digesters

The method for producing paper products begins with wood chips which go through a series of batch preparation and processing stages including being cooked in pressurized vessels called digesters. The heat generated during the cooking process generates pressure within the digester. In the event of an over-pressure condition, ZOOK rupture disks are designed to activate providing relief of excess pressure before damage can occur to vessels and process fluid transfer systems.

Recovery Processing

Black liquor and other byproducts are often reprocessed in recovery boilers to recover the inorganic chemicals for reuse in the pulping process. Some of these byproducts are volatile in nature and pressure relief using ZOOK rupture disks provides safety for process, facility and facility personnel.

Safety Relief Valve Isolation

A safety relief valve automatically releases pressure from a boiler, pressure vessel or other pressure system when the pressure exceeds pre-set limits. A rupture disk is an excellent solution for isolating the pressure relief valve from a chemical process when the process fluid is highly corrosive to the safety relief valves internal components (trim). By installing a rupture disk fabricated from special alloy rather than the valve trim will dramatically reduce the cost of the safety relief valve. In addition, using a rupture disk in combination with a safety relief valve provides zero process leakage, the release of fugitive emissions and allows in-situ testing of the safety relief valve and extends the working life of the safety relief valve.

Conveying Systems

Moving wood chips and pulp using mechanical and pneumatic conveying systems generates combustible dust as well as static which can become a source for ignition. Rupture disks and vent panels from ZOOK aid in providing instantaneous pressure relief in the event of ignition of dust in conveying systems.

Bleaching & Conditioning Tanks

The production of white paper, the wood pulp is bleached to remove any color. Specialty papers used which contain characteristics ideal for printing, packaging, special coatings, pigments or enhanced tensile strength, will go through a variety of additional chemical and heat treatment processes. Heat generated, as well as volatile fumes have the potential of creating pressures which exceed designed operating levels. Rupture disks from ZOOK safely relieve excess process pressure in bleaching and conditioning tanks to maintain system integrity.

Boiler and Boiler Feed Piping

Digesters and other vessels are heated using steam and hot water. In the event of an over-pressure condition, ZOOK rupture disks are designed to activate providing relief of excess pressure before damage can occur to boilers and connected piping.

PRODUCTS BY APPLICATIONS

There are many other pressure relief applications we provide to the Pulp and Paper. Please contact ZOOK for applications not listed.

| Recommended Products | Bulk Storage | Conveying Systems | Digesters | Bleaching & Conditioning Tanks | Recovery Processing |

|---|---|---|---|---|---|

|

Graphite Disks

|

|||||

|

Ultra-Low & Bi-Directional Disks

|

|||||

|

Holders

|

|||||

|

Holders

|

|||||

|

Accessories

|

|||||

|

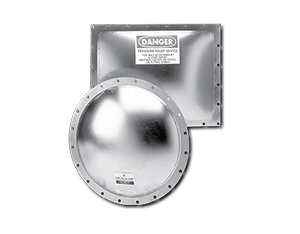

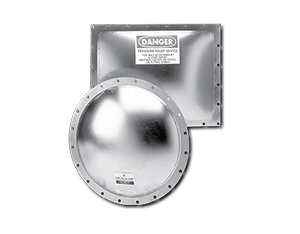

Explosion Vents

|

Applications List

Bulk Storage

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents

Conveying Systems

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Accessories

Explosion Vents

Digesters

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Bleaching & Conditioning Tanks

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Recovery Processing

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories