Forms of energy are generated, distributed, and utilized by the power and energy industry, including electricity, fossil fuels, renewable sources, and nuclear power.

Solutions for

Power & Energy

OVERVIEW

Power plants generate energy through the production of steam to drive turbines and generators. The process of creating and transporting steam under pressure, as well as condensing and recirculating systems require precautions to safely relieve excess system pressure. Volatile and combustible fuel containment tanks, silos and bins benefit from pressure relief devices as well.

COMMON APPLICATIONS

Boiler and Boiler Feed Piping

Most fossil and nuclear fuel power plants rely on the production of pressurized steam to drive turbines and generators to produce electricity. Rupture disks from ZOOK ensure that the systems maintain safe operating pressure levels in boilers and connected steam and condensate piping.

Cooling Towers & Chillers

Cooling towers are large scale heat exchangers used to cool and condense steam after it passes through a turbine as it returns back to the boiler. Installation of ZOOK rupture disks ensure that the system does not exceed preset pressure limits.

Safety Relief Valve Isolation

A safety relief valve automatically releases pressure from a boiler, pressure vessel or other pressure system when the pressure exceeds pre-set limits. A rupture disk is an excellent solution for isolating the pressure relief valve from power plants when the process fluid is highly corrosive to the safety relief valves internal components (trim). By installing a rupture disk fabricated from special alloy rather than the valve trim will dramatically reduce the cost of the safety relief valve. In addition, using a rupture disk in combination with a safety relief valve provides zero process leakage, the release of fugitive emissions and allows in-situ testing of the safety relief valve and extends the working life of the safety relief valve.

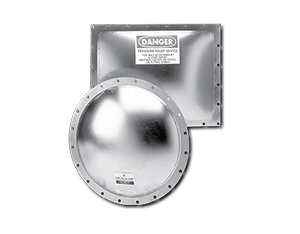

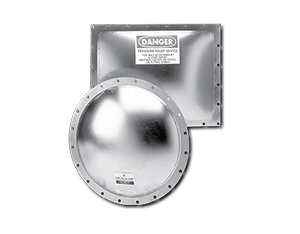

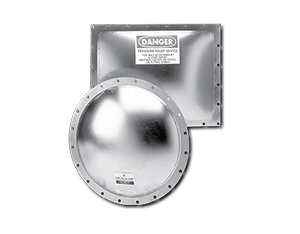

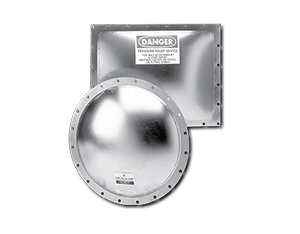

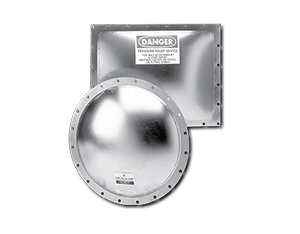

Bulk Storage

Storage tanks containing liquid petroleum, biofuels, natural gas & propane, as well as coal bins containing combustible dust, require safety pressure relief. Rupture disks and vent panels provide instantaneous relief of excess pressure within the storage tank and connected piping.

Pump & Valve Protection

Liquid fuel pumps, chemical feed pumps for conditioning fuel & boiler water, as well as pumps used for moving cooling water, rely on pressure relief devices to protect against over pressurization on the discharge side of the pump. Rupture disks by ZOOK provide relief from backpressure reducing the chances of permanent damage to the pump, valves and process instrumentation.

PRODUCTS BY APPLICATIONS

There are many other pressure relief applications we provide to the Power & Energy Industry. Please contact ZOOK for applications not listed.

| Recommended Products | Bulk Storage | Boiler & Boiler Feed Piping | Cooling Towers & Chillers | Pump & Valve Protection | Safety Relief Valve Isolations |

|---|---|---|---|---|---|

|

Engineered to Order

|

|||||

|

Graphite Disks

|

|||||

|

Ultra-Low & Bi-Directional Disks

|

|||||

|

Plugs

|

|||||

|

Holders

|

|||||

|

Holders

|

|||||

|

Accessories

|

Applications List

Bulk Storage

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents

Boiler & Boiler Feed Piping

Recommended Products

Graphite Disks

Plugs

Holders

Holders

Accessories

Explosion Vents

Cooling Towers & Chillers

Recommended Products

Engineered to Order

Graphite Disks

Plugs

Holders

Holders

Accessories

Explosion Vents

Pump & Valve Protection

Recommended Products

Engineered to Order

Plugs

Holders

Holders

Accessories

Explosion Vents

Safety Relief Valve Isolations

Recommended Products

Engineered to Order

Holders

Holders

Accessories

Explosion Vents