The Food & Beverage industry involves the production and distribution of a wide range of consumable goods, including food and drink products.

Solutions for

Food & Beverage

OVERVIEW

There are many applications and processes in the Food and Beverage industry which benefit from pressure relief provided using rupture disks. From dry bulk storage to sanitary liquid process applications, rupture disks from ZOOK provide instantaneous pressure relief for bulk storage, process vessels and piping used for food and beverage manufacturing.

COMMON APPLICATIONS

Dry Bulk Storage

Dry Bulk Storage Pressure relief for bulk powder storage vessels and pneumatic conveyors which handle grains and other dry food products that can produce methane or combustible dust.

Steam Generators and Vessel Jackets

In the food and beverage industry, heating and control of process vessel temperature is often accomplished using steam jacketed kettles. The closed pressurized system consisting of a steam generator, piping and jacket surrounding the vessel, benefit from incorporating rupture disks which provide pressure relief safety.

Distilling

Distillation systems, which generate both heat and pressure in the production of alcoholic beverages, utilize rupture disks as over-pressure protection devices.

Safety Relief Valve Isolation

A safety relief valve automatically releases pressure from a boiler, pressure vessel or other pressure system when the pressure exceeds pre-set limits. A rupture disk is an excellent solution for isolating the pressure relief valve from a chemical process when the process fluid is highly corrosive to the safety relief valves internal components (trim). By installing a rupture disk fabricated from special alloy rather than the valve trim will dramatically reduce the cost of the safety relief valve. In addition, using a rupture disk in combination with a safety relief valve provides zero process leakage, the release of fugitive emissions and allows in-situ testing of the safety relief valve and extends the working life of the safety relief valve.

Process Vessels

For cookers and kettles, as well as piping which is in contact with food products, ZOOK has engineered rupture disks designed to meet strict sanitary standards.

Boilers

Boilers and piping used to generate hot water and steam to heat process vessels, as well as in facility HVAC systems, use rupture disks to provide relief for overpressure conditions.

Compressed Gas

Compressed gas cylinders and vessels which contain liquid nitrogen and CO2 gas typically used for process cooling, as well as carbonation of beverages, require safety pressure relief provided by rupture disks.

PRODUCTS BY APPLICATIONS

There are many other pressure relief applications we provide to the Food & Beverage Industry. Please contact ZOOK for applications not listed.

| Recommended Products | Dry Bulk Storage | Process Vessels | Steam Generators & Vessel Jackets | Boilers | Distilling |

|---|---|---|---|---|---|

|

Graphite Disks

|

|||||

|

Ultra-Low & Bi-Directional Disks

|

|||||

|

Holders

|

|||||

|

Holders

|

|||||

|

Accessories

|

|||||

|

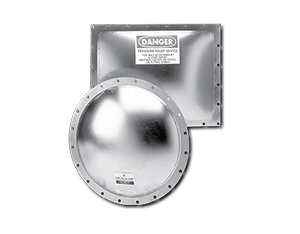

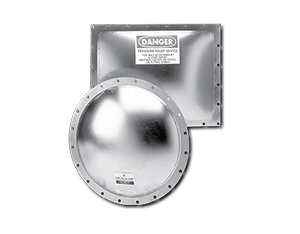

Explosion Vents

|

Applications List

Dry Bulk Storage

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents

Process Vessels

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Steam Generators & Vessel Jackets

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Boilers

Recommended Products

Holders

Holders

Accessories

Distilling

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents