Mineral and resource extraction from the earth drives global economic growth by supporting construction, manufacturing, and energy sectors.

Solutions for

Mining

OVERVIEW

ZOOK’s worldwide team of pressure relief experts recognize the challenges in providing safe and reliable rupture disks for the mining industry, while also recognizing the increasing need to be sensitive to the environment. From dry bulk product applications including coal and ore dust storage to aqueous ore extraction processes (hydrometallurgy) and slurry streams, there are a variety of mining processes that benefit from over-pressurization protection provided by rupture disks from ZOOK.

COMMON APPLICATIONS

Slurry Applications

Slurry applications present the pressure relief industry with unique challenges. These include slurry fluid streams with high solid levels and attendant erosion, solidification in dead-flow areas, esoteric and corrosive chemical combinations, as well as high pressures and demanding cycling conditions. Any release of such material is subject to environmental scrutiny and rupture disks from ZOOK prevent possible ecological impact resulting from over-pressurization of slurry stream piping and containment.

Leaching

Leaching involves the use of aqueous solutions to extract metal ore from metal-bearing materials. There are several leaching methods used including In-situ, Heap, Vat, Tank & Autoclave. All these processes deliver aqueous solutions driven by pumps. At various stages of the leaching process, over-pressure protection to maintain the integrity of the system, as well as protect pumps, valves and process monitoring equipment is essential. In addition, autoclave reactors operate at higher temperatures and use gaseous reagents. ZOOK rupture disks provide vital pressure relief.

Wastewater Treatment

There are several processes in the mining industry which produce water mixed with chemicals and fine particulates that must be treated before being released back into the environment. For metal mines, this can include unwanted metals such as zinc and other materials such as arsenic. Extraction of high value metals such as gold and silver, as well as coal washing may generate slimes containing very fine particles in which physical removal of contaminants becomes particularly difficult. These industrial wastewater treatment systems utilize storage tanks, pumps, valves, and piping which all benefit from the over-pressure protection provided using ZOOK rupture disks.

Blasting Operations

ZOOK leads in standardizing on fine grain graphite as the base disk material, superior in consistency to standard materials. Installation safety, reliability and performance can be further enhanced with ZOOK’s armor rings which eliminate pipeline stresses from affecting the disk.

Extraction

The extraction process relies on combinations of solvents, acids and diluting agents to further extract and purify minerals. Driven by pumps and controlled by valves, these fluid systems benefit from possible over-pressure conditions using rupture disks from ZOOK.

Bulk Storage

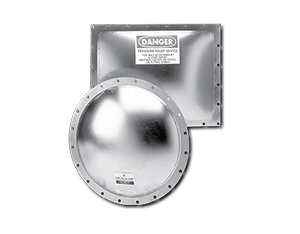

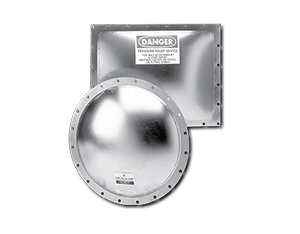

Stored in silos, bins and hoppers, dust generated from coal and other dry minerals has the potential to ignite. Rupture disks and vent panels from ZOOK provide over-pressure protection for silos and conveying systems.

PRODUCTS BY APPLICATIONS

There are many other pressure relief applications we provide to the Mining Industry. Please contact ZOOK for applications not listed.

| Recommended Products | Slurry Applications | Blasting Operations | Leaching | Extraction | Wastewater Treatment |

|---|---|---|---|---|---|

|

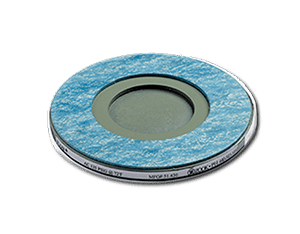

Graphite Disks

|

|||||

|

Ultra-Low & Bi-Directional Disks

|

|||||

|

Holders

|

|||||

|

Holders

|

|||||

|

Accessories

|

|||||

|

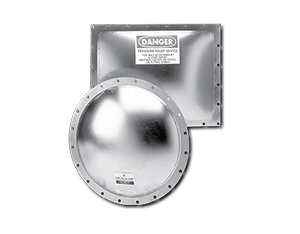

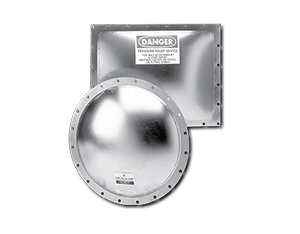

Explosion Vents

|

Applications List

Slurry Applications

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents

Blasting Operations

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents

Leaching

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents

Extraction

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents

Wastewater Treatment

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories