Purifying water and treating wastewater, the water, reverse osmosis, and wastewater treatment industry ensures access to clean water and promotes environmental sustainability.

Solutions for

Water, Reverse Osmosis & Wastewater Treatment

OVERVIEW

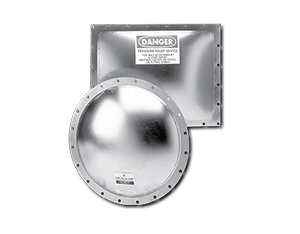

Treatment for drinking water involves the removal of contaminants from raw water to produce water that is pure enough for human consumption. The processes involved in removing the contaminants include physical processes such as settling and filtration, as well as chemical processes which can include disinfection, pH conditioning, and coagulation of dissolved solids. Wastewater treatment plants process wastewater both physically through filtration and chemically as well, before releasing treated water to the environment. ZOOK manufactures rupture disks for water and wastewater treatment systems and are ideal for use with potable water.

COMMON APPLICATIONS

Bulk Storage Tanks

A variety of chemicals are used to treat and condition drinking water including concentrated sodium hypochlorite (bleach) used as a disinfectant and concentrated sodium hydroxide (caustic soda) to balance pH. Both chemicals are very harmful in their concentrated form to facility personnel and the environment and are stored in tanks which require safety precautions for over-pressure conditions.

Desalinization

Desalination is a separation process used to reduce the dissolved salt content of saline water, typically from seawater or groundwater, to a level usable for potable drinking water. One process utilized to accomplish this is reverse osmosis (RO). In the RO process, water from a pressurized saline solution is separated from the dissolved salts by flowing through a water-permeable membrane. Rupture disks from ZOOK, suitable for contact with potable drinking water, are idea for protection against an over-pressure condition.

Safety Relief Valve Isolation

A safety relief valve automatically releases pressure from a boiler, pressure vessel or other pressure system when the pressure exceeds pre-set limits. A rupture disk is an excellent solution for isolating the pressure relief valve from power plants when the process fluid is highly corrosive to the safety relief valves internal components (trim). By installing a rupture disk fabricated from special alloy rather than the valve trim will dramatically reduce the cost of the safety relief valve. In addition, using a rupture disk in combination with a safety relief valve provides zero process leakage, the release of fugitive emissions and allows in-situ testing of the safety relief valve and extends the working life of the safety relief valve.

Filtration Systems

Filtration systems are designed to remove suspended particles, certain types of bacteria and unwanted dissolved substances. Membrane and ultra-membrane filters remove particles and some dissolved solids. Ion-exchange filters use resins to filter out unwanted ions, while other systems remove dissolved solids through a precipitation process. In each of these filtration processes, back pressure is created as large capacity pumps convey water through filters. For pump protection, as well as protection of the integrity of the overall system, rupture disks from ZOOK can provide relief from an over-pressure condition.

Wastewater Treatment

Similar to the water treatment industry, there are several physical filtration and chemical treatment processes that wastewater undergoes before being acceptable for released into the environment. Most of these processes are pump driven and protection from excessive backpressure is provided using rupture disks from ZOOK, preventing potential environmental impact from untreated wastewater.

PRODUCTS BY APPLICATIONS

There are many other pressure relief applications we provide to the Water industry. Please contact ZOOK for applications not listed.

| Recommended Products | Bulk Storage Tanks | Filtration Systems | Desalination | Wastewater Treatment | Reverse Osmosis |

|---|---|---|---|---|---|

|

Engineered to Order

|

|||||

|

Graphite Disks

|

|||||

|

Ultra-Low & Bi-Directional Disks

|

|||||

|

Holders

|

|||||

|

Holders

|

|||||

|

Accessories

|

|||||

|

Explosion Vents

|

Applications List

Bulk Storage Tanks

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Accessories

Explosion Vents

Filtration Systems

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Desalination

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Wastewater Treatment

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Reverse Osmosis

Recommended Products

Graphite Disks

Holders

Holders

Accessories