Pharmaceutics promotes global health and well-being through the development, production, and distribution of medicines and medical products.

Solutions for

Pharmaceutical

OVERVIEW

In the pharmaceutical industry, there are many applications where rupture disks protect against over- pressure and vacuum conditions. ZOOK provides specialized rupture disk pressure relief solutions for pharmaceutical and biotech applications which are additionally designed to maintain sanitary and sterile process conditions.

COMMON APPLICATIONS

Autoclave Pressure Relief

Autoclaves rely on pressurized heat or steam to sterilize components and instrumentation used in biotechnology research and development, as well as production of pharmaceutical products. Rupture disks from ZOOK are utilized to protect against over-pressure conditions while also maintaining an ultra-pure environment for autoclaves and other sterilization equipment.

Process Vessels

Process vessels used in pharmaceutical manufacturing are subject to both over-pressurization, as well as conditions of extreme vacuum. In addition, pressure and vacuum relief devices must comply with sanitary and sterile standards to maintain product purity. ZOOK manufactures rupture disks which meet standards for sanitary and sterile applications.

Compressed Gas

Compressed gas cylinders and containment vessels, as well as cooling systems which utilize liquid nitrogen and other refrigerants, require safety pressure relief provided by rupture disks.

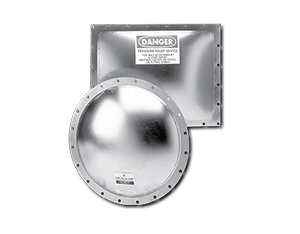

Dry Bulk Storage

Bulk powder storage vessels and pneumatic conveyors which handle pharmaceutical powders can produce combustible dust and benefit from over-pressure protection provided by ZOOK rupture disks and vent panels.

Fermenters/Bioreactors

During the fermentation process utilized in the development and manufacture of pharmaceutical products, a considerable amount of heat is created. Cooling systems are in place to maintain safe operating temperatures and pressures within fermenters and bioreactors. Should cooling systems fail, excess heat generated can result in over- pressurization of the system. If this condition should occur, rupture disks from ZOOK provide pressure relief, thereby maintaining overall system integrity.

Separation Technologies

Chromatography, distillation and other separation methods typically involve containment columns, vessels and piping under pressure. Rupture disks from ZOOK are utilized to protect against over-pressurization.

Safety Relief Valve Isolation

A safety relief valve automatically releases pressure from a boiler, pressure vessel or other pressure system when the pressure exceeds pre-set limits. A rupture disk is an excellent solution for isolating the pressure relief valve from a chemical process when the process fluid is highly corrosive to the safety relief valves internal components (trim). By installing a rupture disk fabricated from special alloy rather than the valve trim will dramatically reduce the cost of the safety relief valve. In addition, using a rupture disk in combination with a safety relief valve provides zero process leakage, the release of fugitive emissions and allows in-situ testing of the safety relief valve and extends the working life of the safety relief valve.

PRODUCTS BY APPLICATIONS

There are many other pressure relief applications we provide to the Upstream Industry. Please contact ZOOK for applications not listed.

| Recommended Products | Autoclave | Fermenters / Bioreactors | Process Vessels | Separation | Dry Bulk Storage |

|---|---|---|---|---|---|

|

Engineered to Order

|

|||||

|

Graphite Disks

|

|||||

|

Ultra-Low & Bi-Directional Disks

|

|||||

|

Holders

|

|||||

|

Holders

|

|||||

|

Accessories

|

|||||

|

Explosion Vents

|

Applications List

Autoclave

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Fermenters / Bioreactors

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Process Vessels

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Separation

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents