The distillery industry involves the process of fermenting raw materials such as grapes, grains, or fruits to produce wines, beers, and distilled spirits.

Solutions for

Fermentation / Wineries / Distilled Spirits

OVERVIEW

There are many applications and processes in the alcohol producing beverage industry which benefit from pressure relief provided using rupture disks. From bulk storage to sanitary process, distillation and fermentation applications, rupture disks from ZOOK provide pressure relief for bulk storage, process vessels and piping.

COMMON APPLICATIONS

Dry Bulk Storage

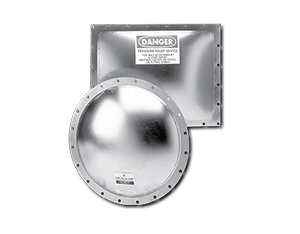

Pressure relief for bulk powder storage vessels and pneumatic conveyors which handle grains, malts and other dry ingredients that can produce methane, as well as combustible dust, benefit from over-pressure protection provided ZOOK rupture disks and vent panels.

Process Vessels

ZOOK provides rupture disks designed to meet strict sanitary standards, provide pressure relief for fermentation tanks, brewing kettles, distillation systems, and piping.

Jacketed Heat Exchangers

In the brewing industry, heating and control of process vessel temperature is accomplished using steam jacketed kettles. The closed pressurized system consisting of a steam generator, piping and heat exchange jacket incorporate rupture disks to provide pressure relief safety.

Safety Relief Valve Isolation

A safety relief valve automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Rupture disks from ZOOK are an excellent solution for isolating the pressure relief valve from a sanitary food or beverage process. In addition, using a rupture disk in combination with a relief valve provides zero process leakage through the safety valve and extends the life of the safety valve, as well.

Chillers

A Chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream. There are several methods used to compress the refrigerant gas during the vapor-compression cycle. Rupture disks provide protection against over pressurization.

Distillation

Systems for producing distilled spirits generate both heat and pressure. ZOOK sanitary rupture disks provide over-pressure protection for the distillation process.

Boilers

Boilers and piping used to generate hot water and steam to heat process vessels, as well as in HVAC systems, use ZOOK rupture disks to provide relief for overpressure conditions.

PRODUCTS BY APPLICATIONS

There are many other pressure relief applications we provide to the Fermentation / Wineries / Distilled Spirits Industry. Please contact ZOOK for applications not listed.

| Recommended Products | Dry Bulk Storage | Process Vessels | Distillation | Heat Exchangers | Boilers |

|---|---|---|---|---|---|

|

Engineered to Order

|

|||||

|

Graphite Disks

|

|||||

|

Ultra-Low & Bi-Directional Disks

|

|||||

|

Holders

|

|||||

|

Holders

|

|||||

|

Accessories

|

|||||

|

Explosion Vents

|

Applications List

Dry Bulk Storage

Recommended Products

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Explosion Vents

Process Vessels

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Distillation

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Heat Exchangers

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Holders

Holders

Accessories

Boilers

Recommended Products

Engineered to Order

Graphite Disks

Ultra-Low & Bi-Directional Disks

Accessories