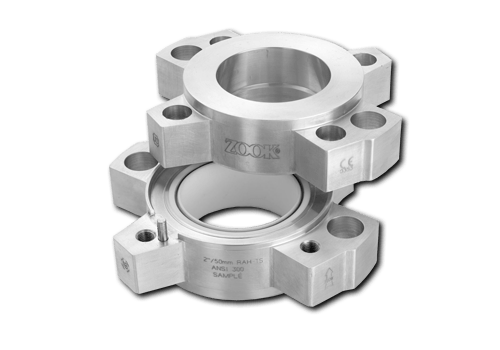

The PTFE Sleeved holder utilizes a Teflon Encapsulated Viton O-Ring as standard. The O-Ring seal prevents the process media getting into contact with the bite-ring outer seal prolonging the life of the holder. ZOOK’s unique double seal prolongs the life expectancy of the holder.

PTFE Sleeve Holder InletHolders

Try Z-SIZE, our user-friendly online tool that calculates the accurate rupture disk size in just minutes

- Features

- Specifications

- Datasheets & Brochures

- Ideal for corrosive applications and reducing the effect of product build-up

- A good cost effective alternative to exotic materials

- PTFE sleeve on all wetted surfaces of the rupture disk holder inlet

- PTFE sleeve is available on the inlet only, and outlet can be Fluoropolymer Teflon Sintered (FS) coated

- The ZOOK PTFE sleeved holder utilizes a Teflon encapsulated Viton O-Ring as standard. The O-Ring seal prevents the process media getting into contact with the bite-ring, this prolongs the high performance of the holder

- PTFE sleeve is available for ZOOK flat seat series reverse acting disk holders in sizes from 1” (25 mm) through to 8” (200 mm) ASME Class 150

- The operating temperature range for the PTFE sleeve is -20ºF to 450ºF (-29ºC to 232ºC)

- The ZOOK design utilizes a mechanical lock to engage Teflon for a rigid assembly

- PTFE sleeves are not torque sensitive and follow standard holder torquing procedures

- Consult ZOOK for further application information

Holder Specifications

PTFE sleeve is available for ZOOK flat seat series reverse acting disk holders in sizes from 1” (25 mm) through to 8” (200 mm)

Need help to choose the rupture disk size for your specific application?

Try Z-SIZE, our user-friendly online tool that calculates the accurate disk size in just minutes!

EXPLORE Z-SIZE