In the world of manufacturing, where precision and safety are paramount, rupture disks play a critical role in safeguarding processes and equipment. One innovative solution that has gained prominence in recent years is the use of double-disk assemblies.

In this blog post, we will explore what double-disk assemblies are, what materials are used in their construction, when they should be employed, and the key advantages they offer.

What are Double-Disk Assemblies?

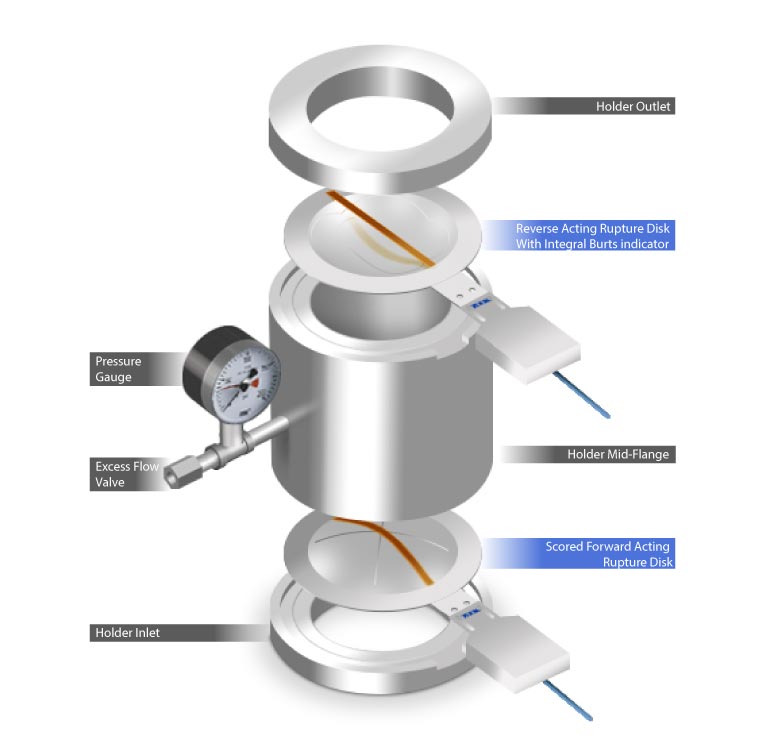

Double-disk assemblies, also known as dual-disk assemblies, are advanced configurations of rupture disks designed to provide enhanced reliability and performance in critical industrial applications. Unlike traditional single-disk setups, double-disk assemblies consist of two rupture disks stacked together, offering a dual-layered protection mechanism.

Materials Used in Double Disk Assemblies

To ensure the utmost durability and reliability, double-disk assemblies are typically constructed from high-quality materials that can withstand harsh operating conditions. Common materials include corrosion-resistant alloys, stainless steel, and nickel alloys. These materials are chosen for their ability to resist corrosion, tolerate high temperatures, and maintain structural integrity under extreme pressure conditions.

When to Use Double Disk Assemblies

Double-disk assemblies are particularly well-suited for applications where an additional layer of protection is essential. Here are scenarios in which these advanced configurations prove beneficial:

Highly Corrosive Environments: In processes involving exceptionally high corrosion, the use of double-disk assemblies provides an extra layer of safety, should one disk be compromised thus preventing costly production stops.

The Occurrence of Variable Back Pressure: In processes and relief pipework configurations where variable backpressure will occur, the use of double-disk assemblies provides an integrated solution guaranteeing pressure relief in unusual circumstances.

Key Advantages of Double-Disk Assemblies

Reliability: With two disks in place, there is a backup layer of protection, reducing the likelihood of a forced production stop, should the primary disc become redundant.

Improved Performance and Versatility: Double-disk configurations, allow for a balanced pressure relief setup, should a single disc not be able to meet all the process and relief requirements. This makes Double-Disk assemblies versatile and adaptable to a wide range of industrial processes.

In conclusion, the incorporation of double-disk assemblies in rupture disk technology represents a significant leap forward in ensuring industrial safety and operational efficiency. These advanced configurations, durable construction, dual-layered protection, and tailored design, offer a reliable solution for industries with more complicated process demands. As manufacturing processes continue to evolve, embracing innovative solutions like double-disk assemblies becomes imperative for companies committed to achieving world-class standards in safety and reliability.