ZOOK’s Fluoropolymer Sintered Graphite Rupture Disk (bursting disk) offers enhanced features when compared to resin impregnated graphite disks. The Fluoropolymer coating is sintered at a high temperature onto a graphite blank. The durable coating seals the graphite material enhancing the corrosive capability and allows the disk to operate at sub-zero to elevated temperatures with minimal effect on the burst performance of the rupture disk (bursting disk).

FS-InvertedGraphite Rupture Disk

Try Z-SIZE, our user-friendly online tool that calculates the accurate rupture disk size in just minutes

ASME (UD) and PED (CE) compliance available

- Features

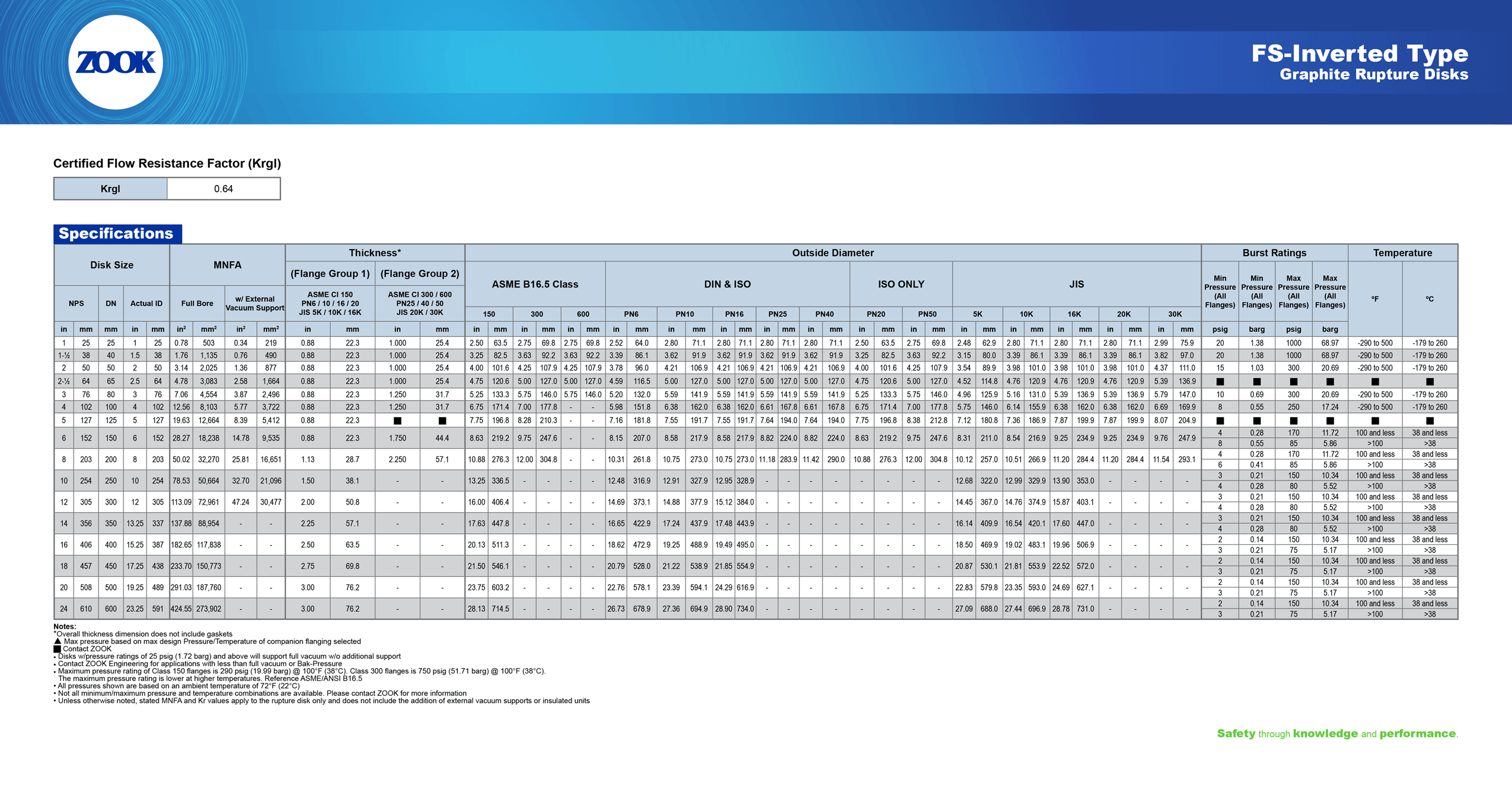

- Specifications

- Installation

- Datasheets & Brochures

- The best choice for highly corrosive and broad temperature range applications

- Non-stick surface conforms to FDA regulations

- Resists product build-up – only the coated flat surface of the disk is exposed to the process media

- Durable coating offers exceptional corrosion resistance

- Available in nominal sizes 1” (25 mm) thru 24” (600 mm) diameters

- Designed to fit industry standard flanges ASME B16.5, ISO and JIS

- Burst ratings to 1,000 psig (68.95 barg)

- 0% manufacturing range is standard

- Operating pressures to 90% of the disk’s marked burst pressure (Contact ZOOK for operating ratio for burst pressures below 40 psig)

- Extended temperature range: –290°F to +500°F (–143°C to +260°C)

- Vacuum support not required for disks with burst pressures of 25 psig and above (Use FS-V Inverted Type for vacuum service)

- All flange group 2 disks are armored

More About The FS-Inverted

Richard Talks

ZOOK’s Fluoropolymer Sintered Graphite Rupture Disk (bursting disk) offers enhanced features when compared to resin impregnated graphite disks.

Need help to choose the rupture disk size for your specific application?

Try Z-SIZE, our user-friendly online tool that calculates the accurate disk size in just minutes!

EXPLORE Z-SIZE