Introduction

When it comes to maintaining the integrity and performance of graphite rupture disks, selecting the correct gasket is paramount. Not only does the material of the gasket play a crucial role, but the dimensions and proper installation are also critical.

This blog will explain why gaskets are so important and how improper gasket selection or installation can impact the performance of your rupture disks.

The Importance of Gasket Material

The choice of gasket material can significantly influence the performance of your rupture disk. For instance, ZOOK advises against using spiral wound gaskets. These gaskets can damage the sealing surface of the rupture disk and may cut the liner material on DUPLEX type disks, compromising the corrosion barrier.

While most other gasket materials are generally acceptable for use with ZOOK disks, there are specific restrictions when using a graphite disk supplied with a ZENSOR®. Soft and electrically conductive gaskets are not recommended in these cases.

Why Gasket Dimensions Matter

The membrane on a ZOOK rupture disk controls when the disk ruptures and if a gasket with improper dimensions is used, it can affect the disk’s performance

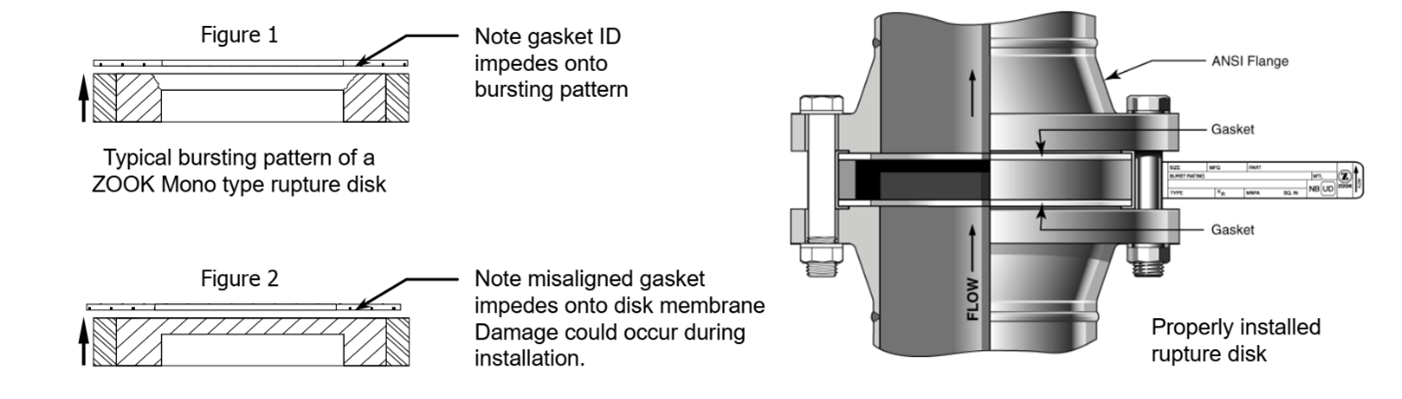

When a MONO disk ruptures, it flares out towards the disk’s outer diameter (OD). If the gasket overlaps this area, it can support the membrane, causing the disk to relieve at a higher pressure than it is rated for (see Figure 1). If a gasket with the same inside diameter as the rupture disk is used and is slightly misaligned during installation, the membrane could become damaged during torquing and gasket compression (see Figure 2).

Ensuring Proper Gasket Dimensions

To ensure your rupture disks perform correctly, it is crucial to follow the gasket dimensions specified in the ZOOK installation guide that is provided with each rupture disk.

For insulated and some other disks, ZOOK provides gaskets supplied attached. If you’re supplying your own gaskets, follow dimensions in the provided ZOOK charts. Correct inside diameter which provides proper clearance ensures accurate burst performance. The correct outside diameter alongside careful installation ensures good centralization. 1/8” (3mm) thick gaskets are recommended.

Rupture Disk Gasket Materials

Gasket materials are typically grouped into four main categories:

- Elastomers

- PTFE (also seen as the brand Teflon™)

- Flexible Graphite

- Compressed Fiber Reinforced (usually an aramid fiber base)

ZOOK stocks Neoprene (Elastomer), Solid Mechanical Grade Teflon™ (PTFE), and KLINGERSIL® C-4401 (compressed fiber) in most standard flange sizes – Class 150/300, PN10, and PN16.

ZOOK uses KLINGERSIL® C-4430+ for our insulated graphite rupture disks.

For specialized applications, alternate materials are available upon request. These can include:

| Elastomers

|

PTFE

|

Flexible Graphite

|

Compressed Fiber Reinforced |

| Viton™ +variants

Buna-N (nitrile) +variants Silicone +variants R-3400 Fluorosilicone Butyl EPDM |

GYLON® +variants

GORE® GR +variants INERTEX® SQ-S |

Grafoil® +variants

|

KLINGERSIL® C-4401

IFG-5500 Thermiculite® +variants Garlock® +variants AFM 34 |

Please note, ZOOK doesn’t make recommendations on gasket materials. The responsibility for ensuring process media compatibility with gasket material lies with the user. Always verify compatibility to maintain the integrity of your system.

Conclusion

Proper gasket selection and installation are critical to the safe and effective operation of graphite rupture disks. Always use gaskets that meet the specifications provided by ZOOK to ensure optimum performance and safety.

ZOOK stocks a wide variety of standard gasket materials and can supply them attached to your rupture disk. For specialized applications, alternate materials are available upon request.

If you have any questions regarding the importance of proper gasket selection and installation for graphite rupture disks, or if you need assistance in choosing the right gasket material for your specific application, please feel free to contact us.

Our team at ZOOK is here to help ensure the optimal performance and safety of your rupture disk systems.