Optimizing Pressure Safety in Desalination Systems

In the complex matter of desalination, particularly Seawater Reverse Osmosis (SWRO) plants, safeguarding against overpressure is critical. These plants operate under varying pressure levels, from low to medium to high, necessitating well-considered protection mechanisms.

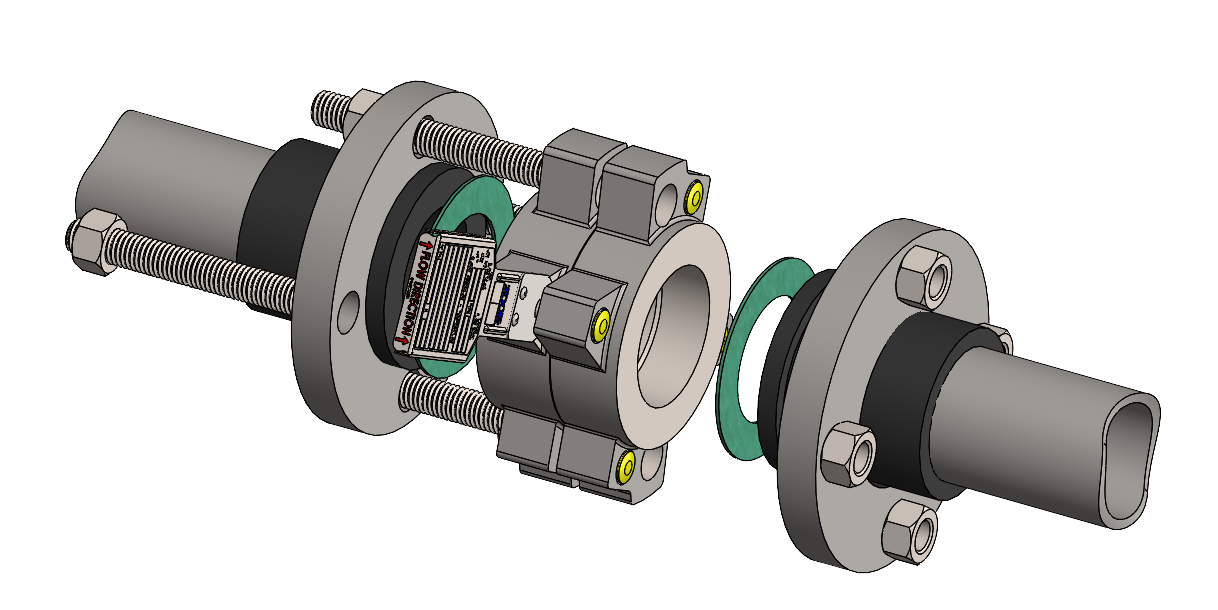

Rupture disks emerge as an exceptional solution for overpressure protection. Their versatility allows them to function either as a primary or secondary safety device or in tandem with pressure relief valves (PRVs). Cost-effective and reliable, metal and graphite rupture disks can be engineered for direct installation between flanges, eliminating the need for disk holders. This design innovation not only reduces installation complexity but also cuts down on additional equipment costs.

Material Considerations in Desalination Applications

Rupture disks and their accompanying holders are traditionally designed for metal flange installation which can generate significant clamping loads. In SWRO desalination applications, the use of ferrous metal pipework poses a risk of contamination due to corrosion. While stainless steel, including advanced duplex materials, offers a corrosion-resistant alternative, it comes at a higher cost.

A prevalent solution is to utilize glass fiber reinforced plastic (GRP) or other plastic-based materials for desalination pipework. These materials, while corrosion-resistant, cannot generate the same clamping loads as their metal counterparts. Here, pre-torque disk holders – like the ZOOK RAH and FAH – become an optimal solution as the holder provides much of the clamping load normally generated by flanged pipework. In high-pressure or high-cycle applications, these holders ensure optimal performance and will give the best service performance.

Advancements in Holderless Rupture Disk Technology

Holderless rupture disks, available in both metal and graphite, offer significant advantages. Graphite disks are noteworthy for their corrosion resistance across all stages of desalination, coupled with high-pressure and vacuum tolerance. These disks also feature superior flow characteristics, making them a prime choice for various stages of the desalination process.

However, it’s important to note that graphite disks fragment upon activation. This necessitates careful consideration of downstream equipment and discharge piping design to ensure process integrity. An alternative is the composite metal disk, often made from 316(L) stainless steel with a plastic film seal (PFA, PEEK™, among others). This design minimizes fragmentation, with only the plastic film potentially separating upon disk activation.

Material Diversity in Rupture Disk Fabrication

The fabrication of metal rupture disks hinges on the availability of suitable foil materials. While certain alloys, such as duplex and super duplex, are not available in foil form, a wide range of high-performance metals are. These include 316(L) stainless steel and various nickel alloys like Hastelloy C276, Inconel, Monel, etc. For added corrosion resistance, plastic film liners can be employed to isolate the disk from corrosive elements.

In scenarios requiring holders, a broad spectrum of engineering materials can be specified, encompassing Duplex, Super Duplex, 316(L), Hastelloy, and more.

ZOOK’s line of high-performance holderless graphite disks are stand-out selections for applications where fragmentation is permissible. Made from graphite and phenolic resin, with optional plastic film liners, these disks are exceptionally corrosion-resistant and suitable for potable water contact. An advanced option includes ZOOK’s fluoropolymer sintered graphite disk, which is FDA-approved for potable water applications.

Conclusion: Tailored Rupture Disk Solutions for SWRO Desalination

ZOOK has crafted solutions for these and many other water and wastewater treatment systems. The spectrum of rupture disk designs is vast, catering to the diverse needs of SWRO desalination plants. Early collaboration with disk manufacturers is vital to identify the most suitable disk, factoring in specific operational requirements and potential cost savings, especially in scenarios where disk holders can be bypassed. This strategic approach ensures optimal safety, efficiency, and cost-effectiveness in pressure relief solutions for desalination plants.