There are many choices for reverse acting rupture disks available on the market today each with very subtle differences making it very difficult if not impossible for even the most knowledgeable Process Engineer to specify the correct design for their application. A mistake could lead to costly damage to connected equipment or an industrial accident. ZOOK has dramatically changed this confusing process, with only the most basic information the correct disk can be selected in minutes.

- WHAT IS THE MEDIUM?

- WHAT IS THE SPECIFIED SIZE?

- WHAT IS THE REQUESTED RUPTURE PRESSURE?

- WHAT IS THE REQUESTED RUPTURE TEMPERATURE?

- WHAT IS THE NORMAL SYSTEM PRESSURE?

- WHAT IS THE NORMAL SYSTEM TEMPERATURE?

- WHAT ARE THE PREFERRED MATERIALS OF CONSTRUCTION?

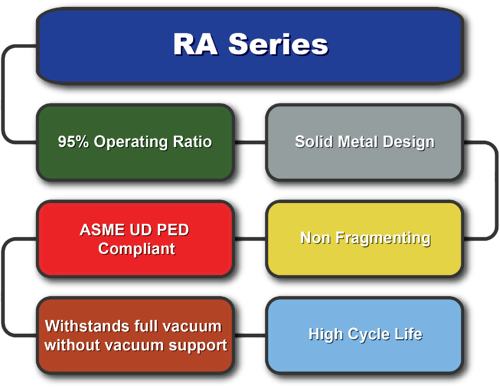

With this basic information, anybody can specify the correct rupture disk design for their application. All the RA series disks include the following standard features and benefits so the user doesn’t have to check for compliance.

HOW TO SELECT THE CORRECT HOLDER DESIGN

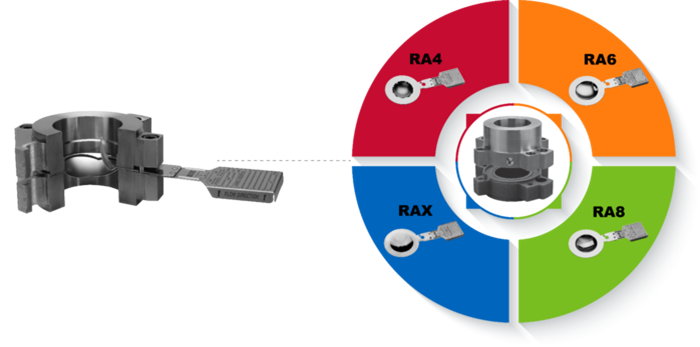

The holder is the installation interphase between the disk and piping system and is very important to obtain optimum performance. ZOOK has made this selection easy with the RAH series of pre-torque holders designed to accept all 4 RA series disk designs and clamp between the customer’s flanges. This unique holder design ensures proper assembly of the disk and holder and guarantees a successful installation of the device into your piping system.

1 Holder (RAH Insert Style Pre-Torque Holder) + 4 Disk Designs = ALL IN ONE SOLUTION

Click on the video below to see all the advantages of the RA Series of reverse acting rupture disks and holders.