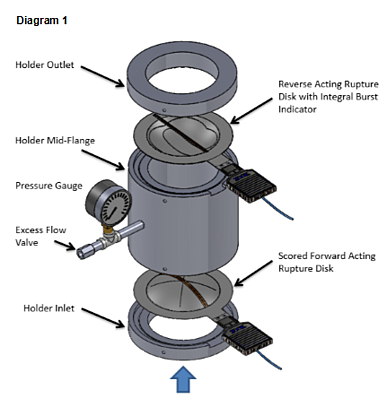

The ZOOK Double Rupture Disk Assembly is such a versatile device to guarantee safety even in the harshest of operating conditions. The assembly consists of using a primary and secondary rupture disk installed in a permanent holder made of three separate components—the inlet, mid-flange and outlet (Diagram 1). Disks are either forward-acting or reverse-acting type or can even be a combination depending on the application.

WHOM WOULD BENEFIT USING A DOUBLE DISK ASSEMBLY?

Environments containing corrosive, toxic or valuable media are ideal for the Double Disk Assembly. In extremely corrosive and toxic applications the process-exposed rupture disk could leak in volatile conditions. A pressure gauge acting as a tell-tale indicator in the mid-flange would indicate the leak, while the secondary rupture disk retains the system leak-free. The primary rupture disk could then be changed out at an opportune time.

Another common application for a double disk assembly is protecting the primary rupture disk from variable back pressure. This condition can occur when multiple rupture disk assemblies are used that are protecting multiple processes. If one rupture disk assembly bursts, the resulting diskharge into the common header could subject the remaining rupture disk assemblies to a transient elevated back pressure condition. Another example would be a flare stack system.

In all cases, the secondary rupture disk withstands the system back pressure, isolating the primary rupture disk. Any change in pressure differential across the primary rupture disk induced by back pressure is eliminated and it will rupture at its marked burst pressure.

The Double Disk Assembly, as a quick opening device, has been used in activating pressure systems and used in many applications in the oil and gas industries. This very fast response is even attainable in large nominal bores.

For more information on double disk assembly, contact us today or request a quote.